Automatic Adjustable Cable Tray Roll Forming Machine Factory

Automatic Adjustable Cable Tray Roll Forming Machine Factory

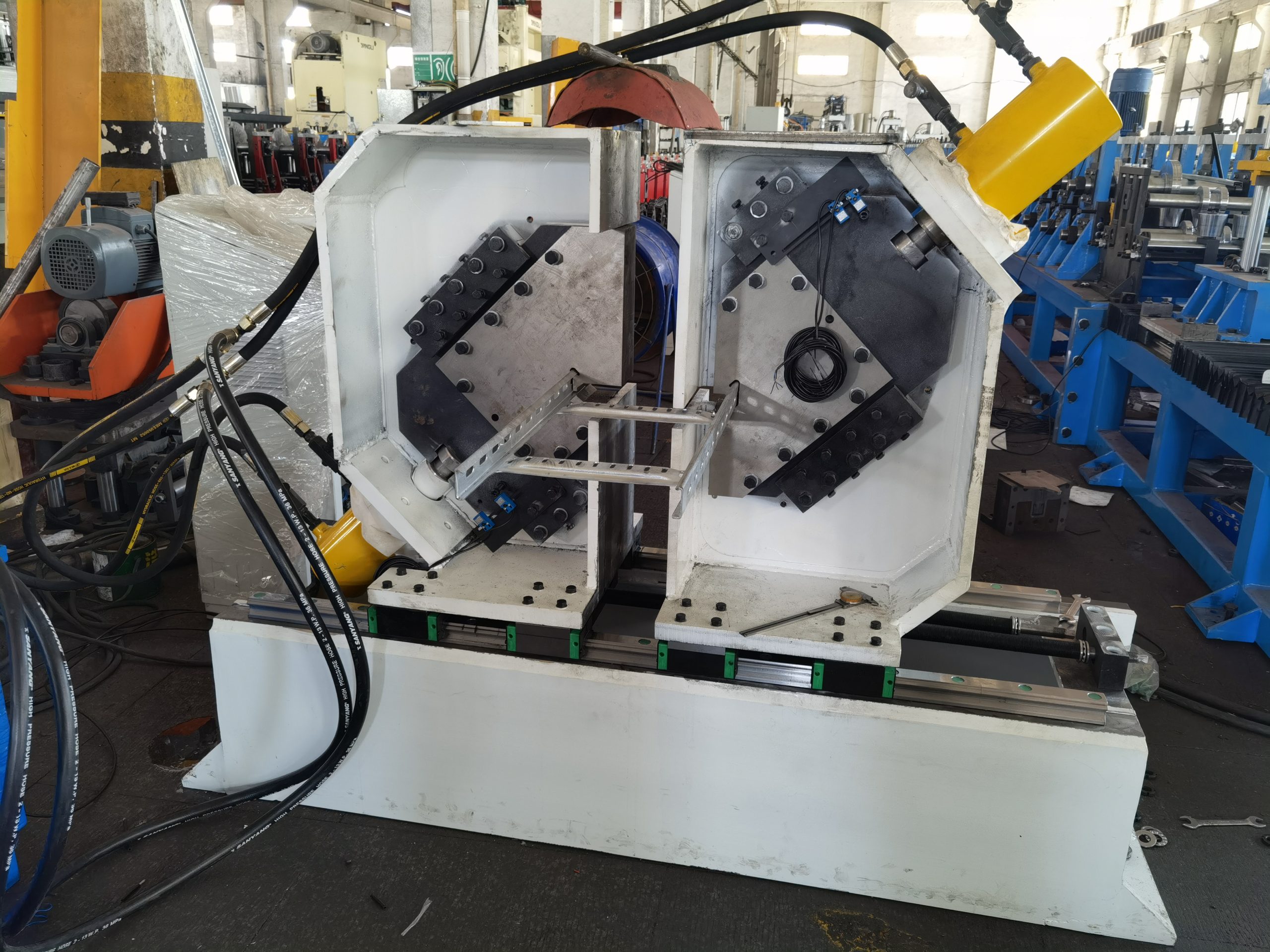

Contact Automatic Adjustable Cable Tray Roll Forming Machine Factory. This fully automatic width and height cable tray roll forming machine can make perforated cable trays from 100-600mm,600-1000mm automatically change size.It uses a economic hydraulic punch station to save costs and easy operation.

Automatic cable tray roll forming machine produced the different kinds cable tray according to different customer requirement.Machine consists of 10T hydraulic uncoiler→2rollers pinch&9rollers flattening→hydraulic two stations punching(servo feeding)→guide feeding→roll forming machine→hydraulic cutting→runout table.

The perforated cable tray production line shall realize the uncoiler, leveling, punching, cutting and roll forming work of the cable tray profile.It does not need to remove any components,and is automatically.converted into the specifications of the required production bridge by PLC setting,the switching of different size specifications.cable tray roll forming machine at best price completed by adjusting the combined mold, and the punching,the fixed length and other processes are all completed at one time,and the production process is fast,stable and safe.

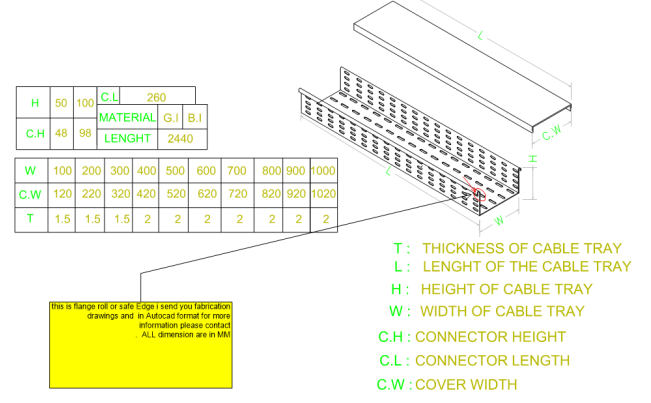

Drawing:

Technology process:

Specification:

| Cable tray ladder roll forming machine | ||

| NO | NAME | TECHNICAL DATA |

| 1 | Forming station | Normally 28stations or more.according to customer drawing to design. |

| 2 | Machine structure | wall panel style or cast iron rack system |

| 3 | Punching | hydraulic punching or merchnical press. |

| 4 | Cutting | Hydraulic post cutting or pre-cutting |

| 5 | Out table | Manual or automatic |

| 6 | Computer control system(PLC) | Panasonic or Simens |

| 7 | Roller material | GCr15,Cr12,SKD11 quenching treatment:HRC58-62(optional) |

| 8 | Driving | Chain drive or gearbox drive |

| 9 | Forming speed | 0-15m/min |

| 10 | Raw material request: | thickness 1.2-2.0mm,Q235,Q345 galvanized steel and hot rolled steel,stainless steel. |

| 11 | Main shaft diameter | Φ110mm. |

| 11 | How to adjust sizes? | .Size make:height:50-100mm(adjustable)、width:100mm -1000mm(adjustable)Different specifications are automatically traversed by inputting data through PLC touch screen. |

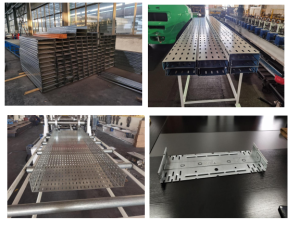

Customer case:

1.Cable ladder roll forming machine sold to domestic

2.Cable ladder roll forming machine sold to Russia

3.Cable ladder roll forming machine sold to Saudi arabia

4.Cable ladder roll forming machine sold to Iraq

5.Cable ladder roll forming machine sold to Indonesia