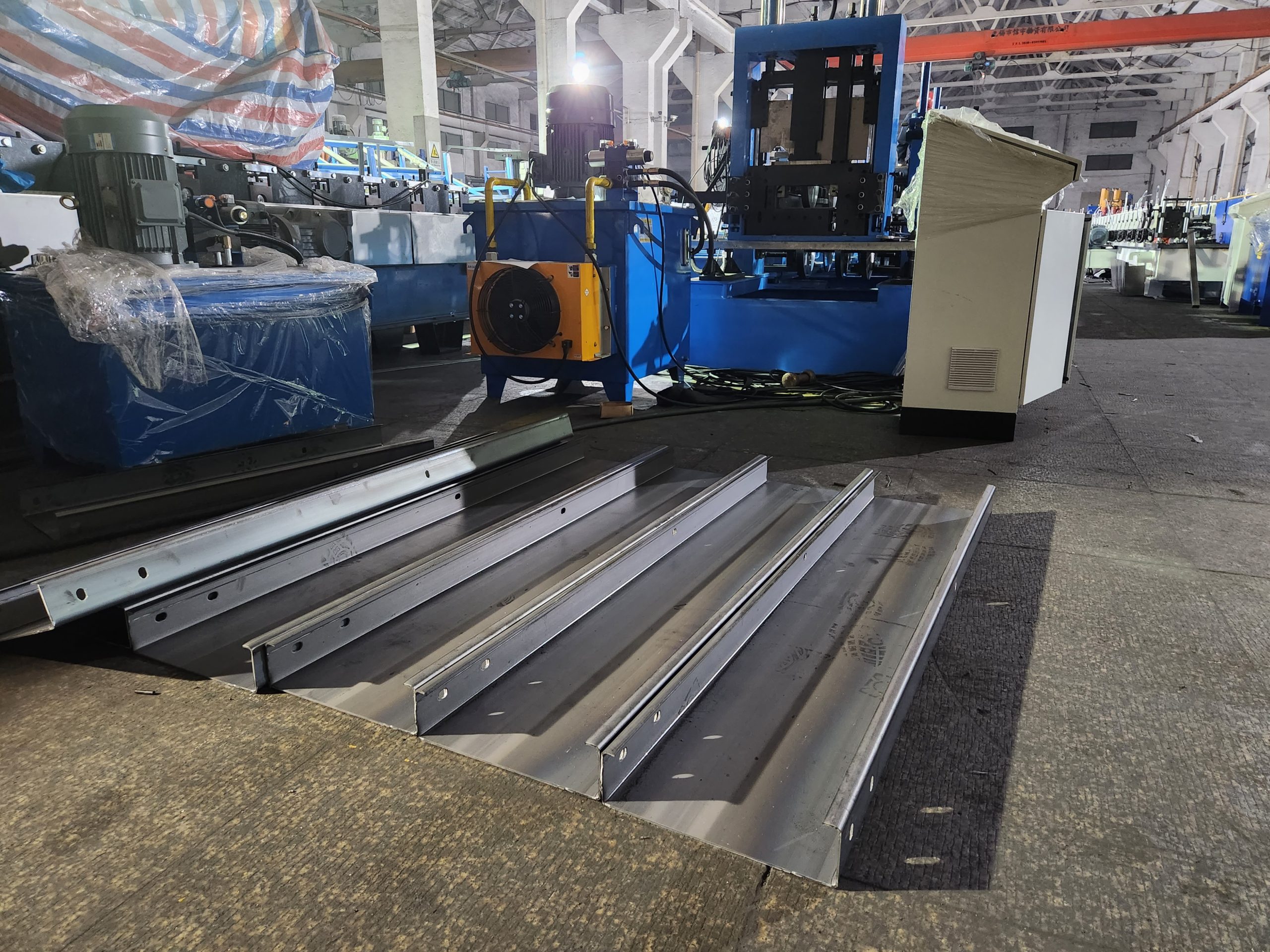

Automatic CZUM Changeable Purlin Cold Roll Forming Machines

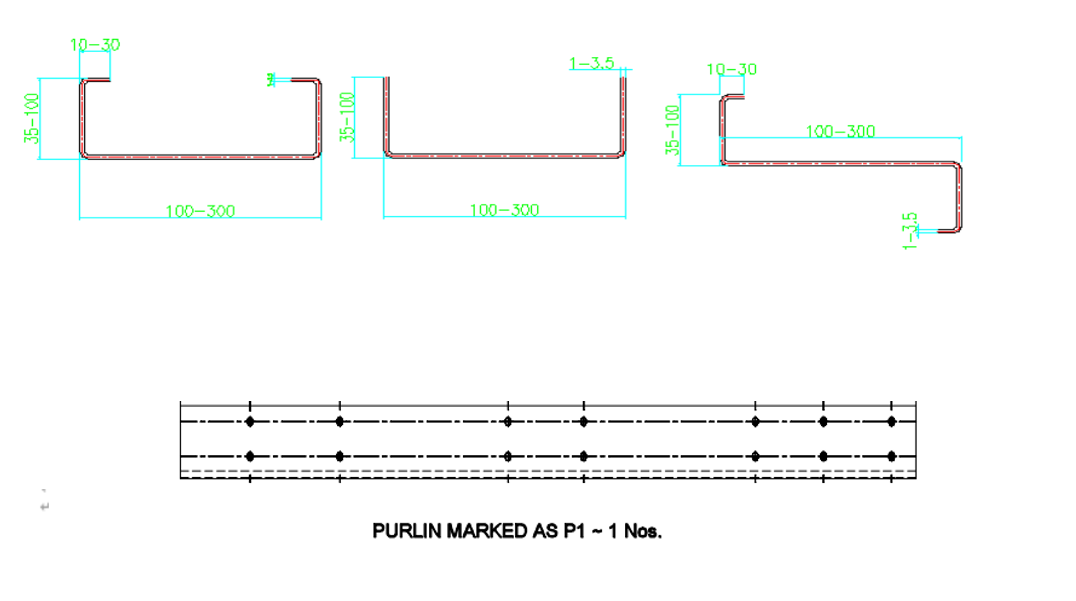

CZUM Changeable Purlin Cold Roll Forming Machines is the most popular and has an extensive use in metal building Systems, huge roofing solutions,construction and renovation projects etc. Our Purlin cold roll forming machine could produce C purlin, U purlin, Z purlin, M purlin machineable size range as follow:Width:0-300mm, Height: 50-100mm, Thickness:1.5-3mm. Raw material could be: cold-rolled steel, Galvanized steel, PPGI, high-tensil steel. The finished purlins meet JIS G standard, ASTM International Standard, AS/NZS International Standard etc.According to your section profile, size range, thickness range we could provide you different solutions of purlin cold roll forming machine to manufacturer a complete range of structual purlins(height and width change using automatic system by motors):

Only to produce C/U section, change time: few seconds.

C/U/Z section-manual change whole line from C to Z, change time:10 minutes

C/U/Z/M section-manual change 4 stations from C to Z, change time:2 minutes

C/U/Z/M section-automatically change from C to Z, change time: few seconds

Regarding the cutting unit ,you can choose the pre-cut, post cut or both. Gearbox driving system with cast iron stands are more durable and recommendable.

If you only need to produce few sizes, we also suggest manually change sleeves, it’s more affordable.We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your every need.

C-Z quick interchangeable machine adopts a special structure:Quick C to Z interchange: The rollers for C & Z are changed very quickly without dismantle any parts,The forming tooling is simply unclamped,rotated through 180 degree, and re-tightened.No tooling or spacers are removed or changed. Quick, Easy, Simple.

- Purlin specifications:For C purlin: 150×50, 150×65, 150×75, 175×50, 175×65, 175×75, 100×50, 100×38, 75×50, 75×38.

- For Z purlin: 150×50, 150×65, 150×75, 175×50, 175×65, 175×75,Coil thickness:1.5-3mm, Q235, G350, G550, GI & CR, HR.

C channel purlin cold roll forming machine Drawings:

CZU Purlin Cold Roll Forming Machine Technological process:

U/C/Z Purlin Cold Roll Forming Machines Specification:

| Automatic CZUM purlin cold roll forming machine. | ||

| NO | NAME | TECHNICAL DATA |

| 1 | Forming station | Up layer:20stations,down layer:22stations.accroding to customer drawing to design. |

| 2 | Machine structure | Shaft archway gearbox transmission on both sides of CZM. |

| 3 | Cutting | Hydraulic post cutting or servo track cutting. |

| 4 | Out table | Manual or automatic. |

| 5 | Computer control system(PLC) | Panasonic or Simens. |

| 6 | Roller material | GCr15,Cr12,SKD11 quenching treatment:HRC58-62(optional). |

| 7 | Forming speed | 0-20m/min. |

| 8 | Raw material request: | thickness 1.5-4mm,Q235,Q345 galvanized steel and hot rolled steel.carbon steel,cold steel. |

| 9 | Main motor power | 11KW+37KW. |

| 10 | Total weight | about 20000Kgs. |

| 11 | Punching unit | Hydraulic punching station. |

| 12 | Leveling device | Leveling diameter:Φ100,two rollers pinching+7rollers leveling. |

| 13 | How to quick change CZUM profile? | Size change: The form tooling is unclamped,slid into the correct position by PLC control. No special tools, no spacer changed. Infinite sizes are possible.

Only input data in touch screen can adjust any size automatically, by motor driving stations moving accurately on linear guiderail with encoder. |

| 14 | Stations

|

16-20stations,Quenched using bearing steel. |

Customer case:

1.Automatic CZUM purlin cold roll forming machine Sold to Argentina.

2.Automatic C purlin cold roll forming machine Sold to Colombia.

3.Automatic C purlin roll forming machine Sold to Philippines.

4.CZ Purlin cold roll forming machine Sold to Dubai.