Folding Box Plate Roll Forming Machine Manufacturer in China

Category Cold Roll Forming Machine

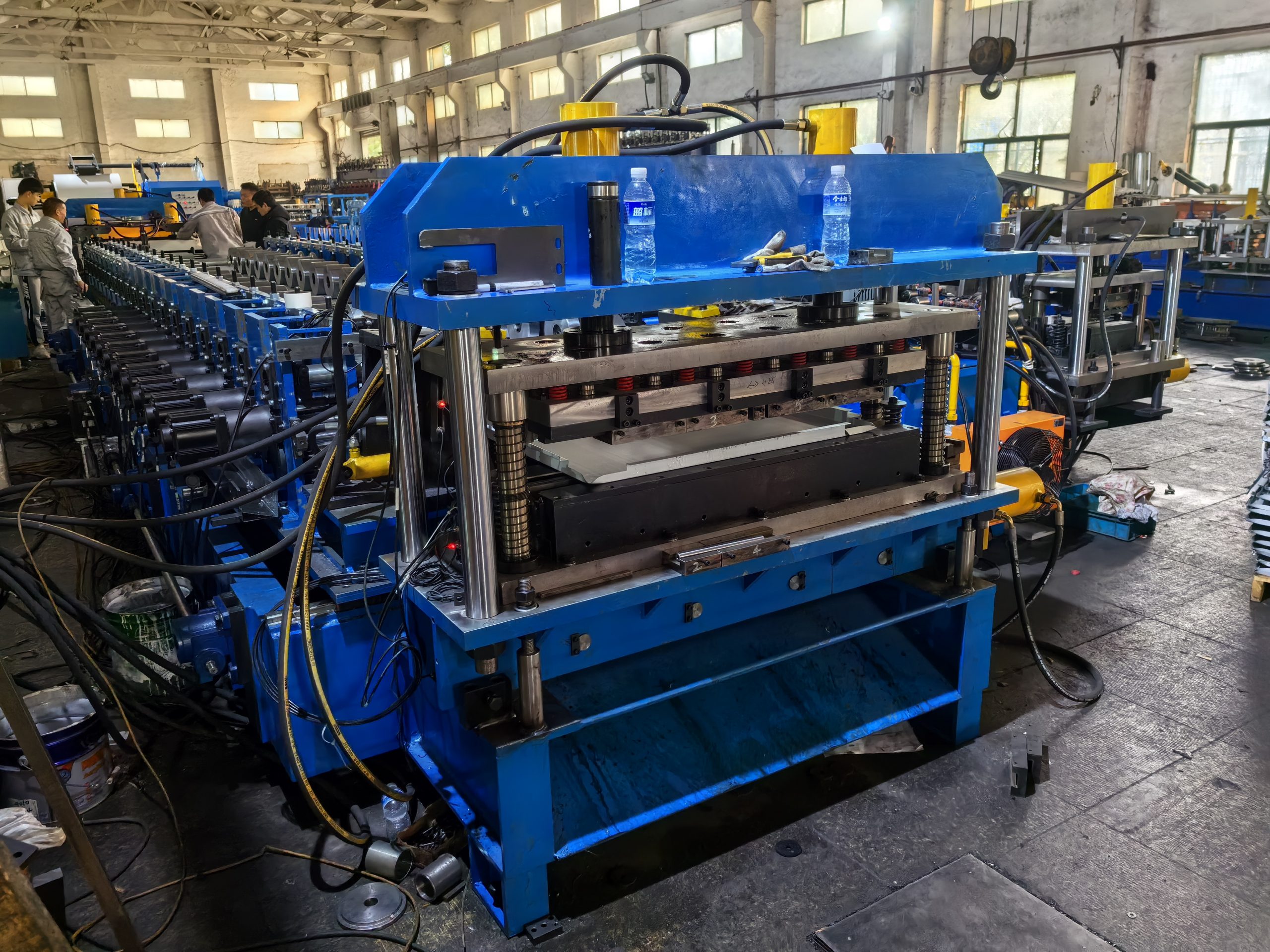

Folding Box Plate Roll Forming Machine Manufacturer in China

Find Folding Box Plate Roll Forming Machine Manufacturer in China. Single adjustable Box plate roll forming machine consists of 5T uncoiler,conveying platform,punching gap,roll forming machine,cutting,turnover edge,4m conveying platform,hydraulic station,PLC,runout table.and they are used as racks and shelves for supporting the daily commodities in supermarkets and shops.

Steel box plate making machine drawing:

Box board roll forming machine process:

Uncoiler—–Feeding—–Two rollers feeding—–Punching two edges—-Roll forming machine— post cutting—–turnover edges—–4m conveying roller table—-Runout table.

steel box plate roll forming machine specification:

| NO | NAME | TECHNICAL DATA |

| 1 | Forming station | Normally 14stations or more.accroding to customer drawing to design. |

| 2 | Machine structure | wall panel style or torii archway. |

| 3 | Cutting | Hydraulic post cutting or pre-cutting |

| 4 | Out table | Manual or automatic |

| 5 | Computer control system(PLC) | Panasonic or Simens |

| 6 | Roller material | GCr15,Cr12,SKD11 quenching treatment:HRC58-62(optional) |

| 7 | Inverter : | Yaskawa,Siemens,Mitsubishi, panasonic (option Brand). |

| 8 | Driving | Chain drive or gear drive. |

| 9 | Forming speed | 0-20m/min |

| 10 | Raw material request | thickness 0.6-1.2mm,Q235,Q345 galvanized steel and hot rolled steel.cold rolled steel.stainless steel. |

| 11 | Punching gap | Hydraulic drive,punching gap on plain plate. |

| 12 | Cutting | Hydraulic drive,cutting after forming. |

| 13 | Coil width | Width:100㎜~520㎜ |

Customer case:

Box plate roll forming machine sold to Malaysia.

Box plate roll forming machine sold to Vietnam.

Folding box plate roll forming machine components: