Cable ladder tray roll forming machine

Cable ladder roll forming machine can make perforated cable trays from 50-100,200-600mm automatically change size.Cable ladder machinery is commonly used for cable management in commercial and industrial construction.This intelligent cable ladder making machine could produce different types of cable trays like: Solid bottom cable tray, Trough cable tray, Channel cable tray, Perforated cable tray, Non perforated cable tray and Trunking cable tray etc. with different raw materials like: hot-dip galvanized steel, pre-galvanized steel, hot-rolled and cold-rolled steel, stainless steel and aluminum. Thickness range of material is 0.6mm-1.2mm or 1-2mm. You could set up 10 different lengths for cable tray.We can make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your every need. Whichever line you choose, the quality of ladder cable tray forming machine will ensure you obtain perfectly functional profiles.

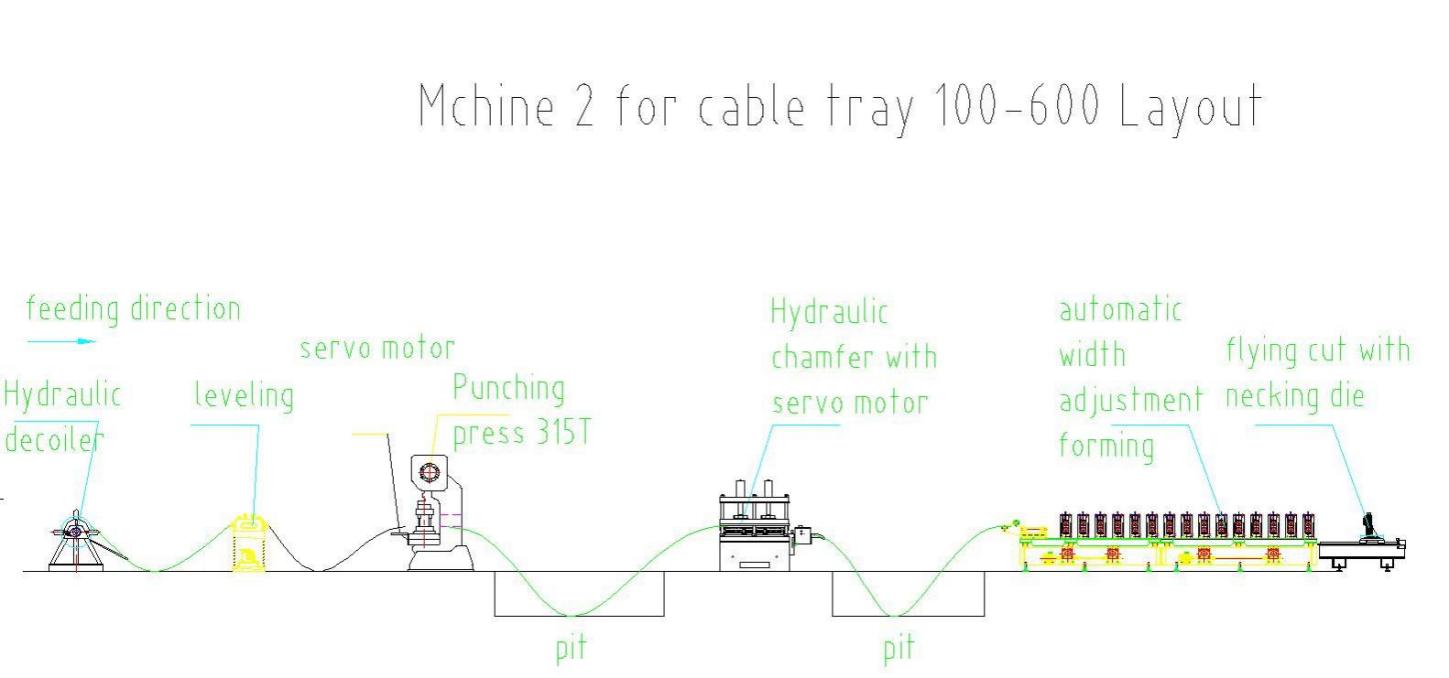

Drawing:

Specification:

| Cable ladder roll forming machine | ||

| NO | NAME | TECHNICAL DATA |

| 1 | Forming station | Normally 22stations or more.according to customer drawing to design. |

| 2 | Machine structure | wall panel style or cast iron rack system |

| 3 | Punching | Hydraulic punching or 315T merchnical press. |

| 4 | Cutting | Hydraulic post cutting or pre-cutting. |

| 5 | Out table | Manual or automatic. |

| 6 | Computer control system(PLC) | Panasonic or Simens. |

| 7 | Roller material | GCr15,Cr12,SKD11 quenching treatment:HRC58-62(optional) |

| 8 | Driving | Chain drive. |

| 9 | Forming speed | 0-16m/min. |

| 10 | Raw material request: | thickness 0.6-1.2mm,Q235,Q345 galvanized steel and hot rolled steel,stainless steel. |

| 11 | Main shaft diameter | Φ70mm. |

| 11 | How to adjust sizes? | With fully automatic adjustment from one width to another width it just needs few seconds to finish changing. |

CCable ladder roll forming machine sold to Russia.

Cable ladder roll forming machine sold to Argentina:

Cable ladder roll forming machine sold to China Group company:

Cable tray roll forming machine components:

Final Products:

Final Products: