Solar Struct Roll Forming Machine

We have very rich experience in producing Solar Struct Roll Forming Machine, and we can customize them according to different customer drawings. If you are interested, welcome to inquire for details.

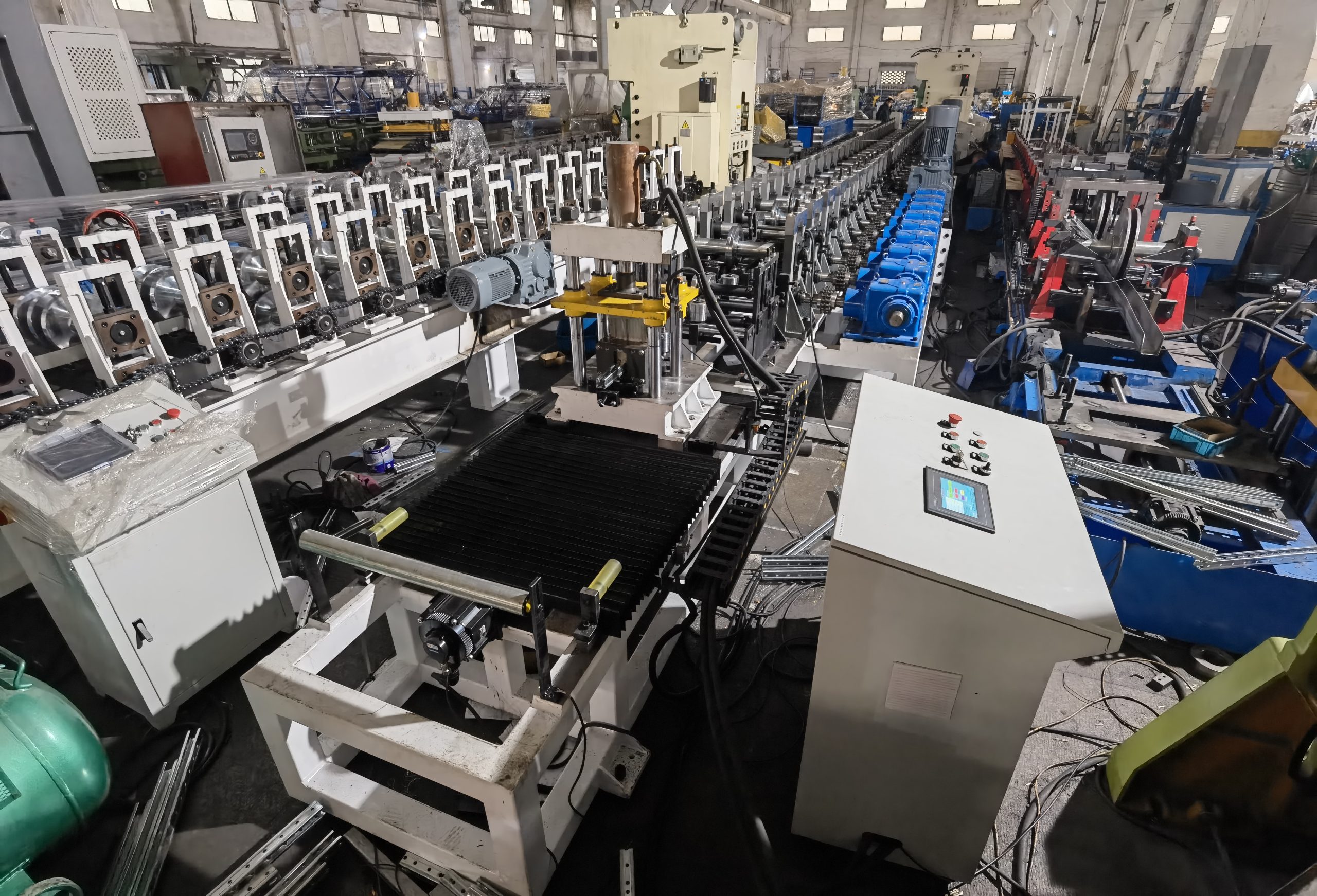

The Solar Struct Roll Forming Machine is the production line provided by our factory for the solar company.The solar bracket has stable performance mature manufacturing process with high carrying capacity simple installation and is widely used in civil industrial solar bracket and solar power plants .

The solar panel roll forming machine can produce a variety of cross-section specifications and support profiles by switching.It is quick and convenient to change the profile and one person can operate the whole line. The PLC totally controls the uncoiler leveling and feeding fixed-length punching roll forming follow-up cutting and discharging. It can set multiple sets of parts data tasks at one time automatic production and remote control.

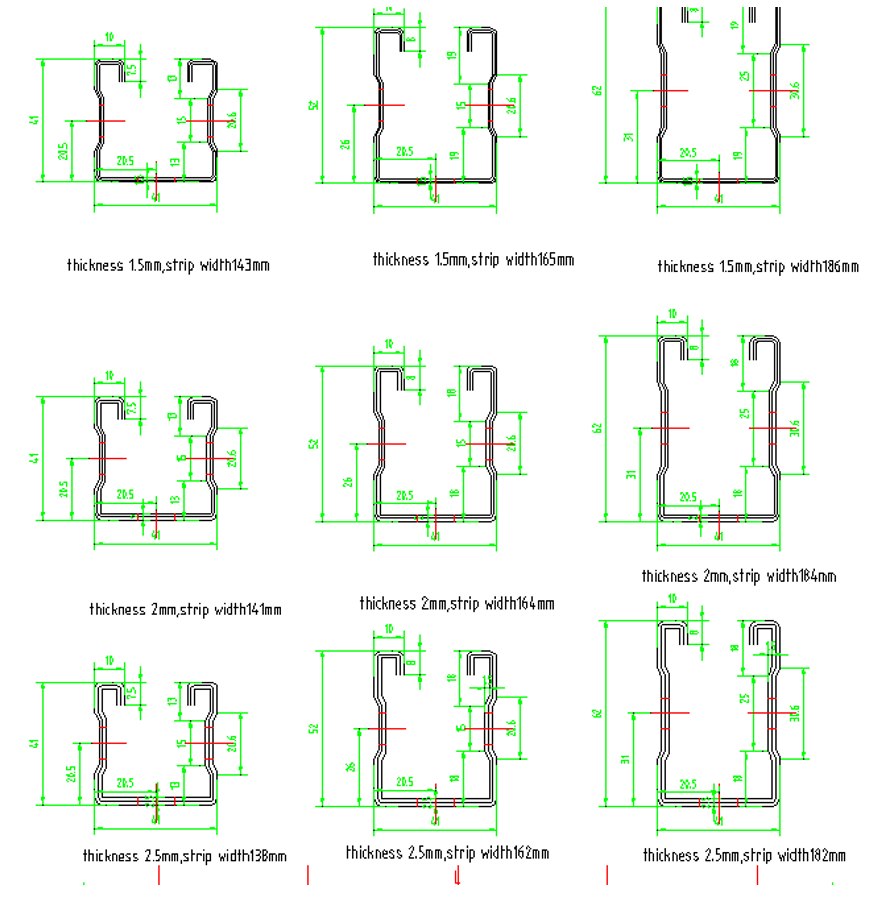

The function of the bracket is to protect the photovoltaic modules from damages such as light, corrosion and strong wind for 30 years.There are many materials for the bracket.The raw material of photovoltaic bracket can be carbon steel Q235.Hot-rolled and cold rolled steel, Hot-dip galvanized sheet,Pre-Galvanized Steel, Mill(Plain/Black) Steel, Aluminum coil, Stainless Steel etc.The average galvanized thickness is 65μm, and the basic thickness of the bracket can be equal to or greater than 2.5mm. Corrosion resistance is very good.We can make the most popular profile is 40×21, 41×41, 41×62,41×52,27×16.also we can make 3-5 profiles in one machine according to change the spacer and several rollers manually.the machine speed can attach to 0-20m/min.

Nowerdays we already exported the solar structure bracket machine to Turkey,Saudi arabia,USA,Iraq,India,Qatar,Argentina,Pakistan,Turkey,Dubai.We cooperate with the largest photovoltaic brackets company in the United States and exclusively supply photovoltaic bracket products to USA customers per month by containers.If you interested in this machine,we could send the video or welcome you can visit us.

Drawings:

Technogical Process :

Specification:

| NO | NAME | TECHNICAL DATA |

| 1 | Forming station | Normally 18stations or more.accroding to customer drawing to design. |

| 2 | Machine structure | wall panel style guide pillar style or forged Iron station |

| 3 | Punching | hydraulic punching or merchnical press. |

| 4 | Cutting | Hydraulic post cutting or fly shear |

| 5 | Out table | Manual or automatic |

| 6 | Computer control system(PLC) | Panasonic or Simens |

| 7 | Roller material | GCr15,Cr12,SKD11 quenching treatment:HRC58-62(optional) |

| 8 | Driving | Chain drive or gearbox drive |

| 9 | Forming speed | 0-25m/min |

| 10 | Raw material request: | thickness 1.0-2.5mm,Hot-rolled and cold rolled steel,galvanized sheet, Pre-Galvanized Steel, Aluminum,Stainless Steel |

| 11 | How to adjust sizes? | Diffferent sizes adjustment according to change the spacers and rollers by manually,this is very simple,we could send you video to teach you step by step. |

Customer case:

1.Solar photovoltaic bracket roll forming machine we sold to Saudi arabia.

2.Solar photovoltaic bracket roll forming machine we sold to Iraq.

3.Solar photovoltaic bracket roll forming machine we sold to China.

4.Solar photovoltaic bracket roll forming machine we sold to USA.

5.Final solar bracket products for reference: