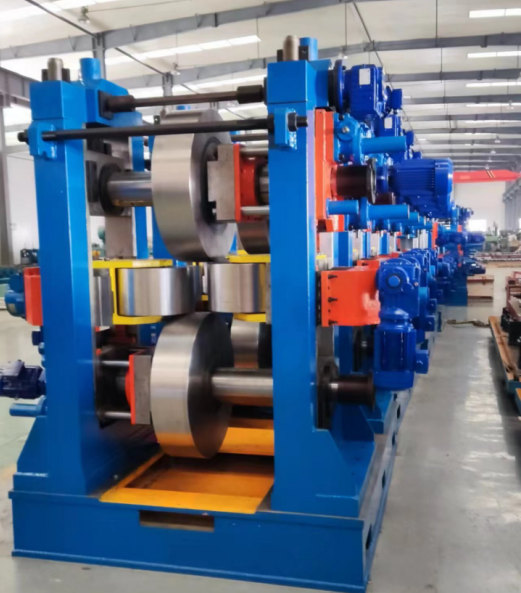

China Automatic Pipe Welding Machine

china automatic pipe welding machine adopt the combined roller and panel construction.One set of roller can cover most of the sizes and share 90% of the roller.The roller adopting the panel construction contact with the strip deformation region.Which can reduce the area.the friction and power consumption of forming roller.At the same time it can save about 5% raw material.

1.Roll Sharing: One set of rolls for all pipe sizes. Reduce roll cost up to 90%.

2.One-click change: Automatic size changing using servo control system. Ready by one-click.

3.Rapid adjustment: Size changing in 8 minutes. Reduce adjustment time up to 90%.

4.Save labor: Low labor intensity. Need only 2 workers for size changing.

5.Save material: Reduce at least 5% raw material.

Welded pipe production line Flow chat:Storage coil-Coil feeding-Uncoiler-Feeding&leveling-Straightening-Butt welding&cutting-Pinching&reverse-Accumulator-Reverse-Forming-High frequency welding-Delete out burrs-Weld leveling-Cooling-Sizing-Straightening-Length cutting-Collection.

High frequency ERW pipe mill line Specification:

| NO | NAME | TECHNICAL DATA |

| 1 | Outer diameter | 80x80mm~200mmx200mm |

| 2 | Wall thickness | 3.5mm~10.0mm |

| 3 | Speed | 0-35m/min |

| 4 | Coil width | 320mm-800mm |

| 5 | Max coil weight | ≤16000kg |

| 6 | Uncoiler | OD:Φ1200~1600mm ID:Φ500mm~Φ600mm |

| 7 | Turkey head | 2sets. |

| 8 | Cutting saw | Computer hot cutting saw |

| 9 | Total power | About 1250KW |

| 10 | Raw material | Q195,Q235,Q355 |

| 11 | Square pipe | 80×100-150×250 |

| 12 | Machine dimension | 160mx43m |

Technical form of HF welding pipe machine:(this is only for reference,we can design according to different customer requirement).

| Model | Wall thickness | Square pipe(mm) | Speed(m/min) | Rectangle pipe |

| BP100 | 1.5mm~5.0mm | 40×40-100×100 | 20~70 | 30×50mm-80×120mm |

| BP150 | 2mm~6.0mm | 70×70mm-150×150mm | 20~60 | 60×80mm-100×200mm |

| BP200 | 2.5mm-8.0mm | 80×80-200×200 | 10~40 | 80×100mm~160×180mm |

| BP300 | 4.5mm-12mm | 120X120-300×300 | 12-30 | 80×100mm-150×250mm |

| BP400 | 6.0~16.0 | 200×200~400×400 | 12-25 | 200×250-350×450 |

| BP500 | 8.0-20.0 | 250×250-500×500 | 0-20 | 250×300-450×550 |