Four Rows Drywall Stud and Track Roll Forming Machine

This four rows drywall Stud and Track Roll Forming Machine can make 8 different shapes in four rows Drywall Stud and Track Roll Forming Machine.this is very economical and save space machines for construction buildings.This fours rows Drywall Stud and Track Roll Forming Machine can make omega/CU/angle in one machine,totally can make 8 different profiles in one machine.This is very economical and save space machine which is very popular in abroad customer.Light steel keel is an important material in the construction industry, they can be used to make light steel keel ceiling, light steel keel partition wall.

This material can be seen in major shopping malls and major office buildings. The light steel keel machine is a tool used to make the light steel keel structure. Different brands of light steel keel machines have different prices, but they are the best helpers for the production of keels. They have better bending ability and high machine production efficiency can make the keel structure to the greatest extent. And they have maximum security measures. The size of the machine is small, the space is small,the movement is convenient and simple, and the long-term use will not cause deformation or safety hazards.Has extremely high hardness. The molds of the machine are customized with special materials and have very special performance and quality.

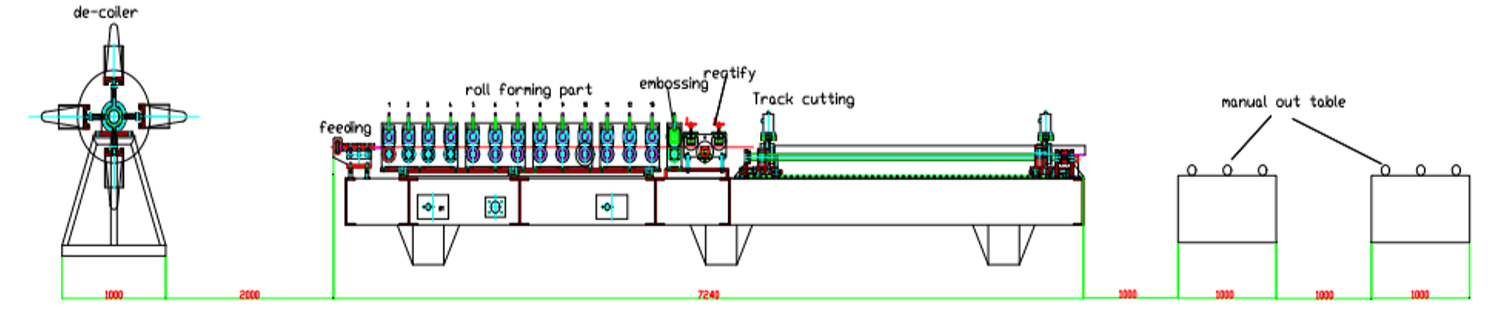

Drawing:

Technology Process:

Specification:

| NO | NAME | TECHNICAL DATA |

| 1 | Forming station | Normally 16stations or more.accroding to customer drawing to design. |

| 2 | Machine structure | wall panel style,guide pillar style or cast iron rack system |

| 3 | Cutting | Hydraulic post cutting or fly shear |

| 4 | Out table | Manual or automatic |

| 5 | Computer control system(PLC) | Panasonic or Simens |

| 6 | Roller material | GCr15,Cr12,SKD11 quenching treatment:HRC58-62(optional) |

| 7 | Inverter : | Yaskawa,Siemens,Mitsubishi, panasonic (option Brand). |

| 8 | Driving | Chain drive or gearbox drive. |

| 9 | Forming speed | 0-30m/min |

| 10 | Raw material request: | thickness 0.3-0.8mm,Q235,Q345 galvanized steel and hot rolled steel.cold rolled steel.stainless steel. |

| 11 | Main motor | 15Kw,voltage:220V,60Hz,3P |

| 12 | Punching | Hydraulic punching with two moulds. |

Customer case:

1.Double row keel forming machine we sold to customer to Iraq.

2.Double row omega and hat machine we sold to customer in Argentina.

3.Double row angle&C machine we sold to USA.