Oem KBK Crane Rail Roll Forming Machine

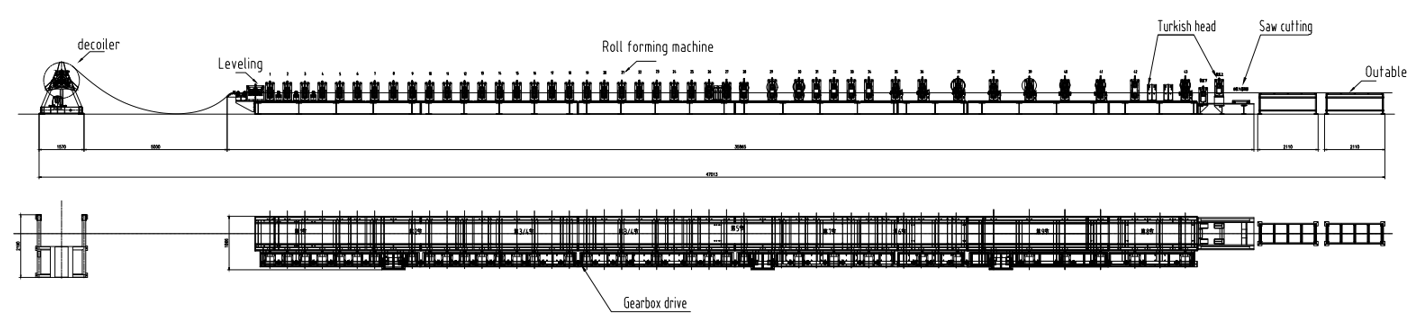

Oem KBK Crane Rail Roll Forming Machine consists of Decoiler-Leveling-Roll forming-Turkish head-Fly saw cutting-Out table.The crane standard component KBK is composed of components such as suspension devices, rails, turnouts, traveling trolleys, electric hoists, mobile power supply devices (slide wires), and control devices. Simply hanging on the roof or beam frame of a factory building can achieve direct transportation of materials in the air.

Therefore, KBK light rail crane forming machine widely used in material transportation links or systems in various industries.KBK track is a necessary equipment for major automobile manufacturers and suppliers of high-quality products. KBK rail has high strength, good rigidity, light weight, and strong adaptability. The KBK monorail crane roll forming machine can be manually operated, and can also achieve automatic and semi-automatic operations, meeting various forms of process layout requirements.The KBK rail is the key equipment that constitutes the KBK crane, and its main function is to operate the crane.

KBK rail forming machine Drawings:

Technological process:

Specification:

| NO | NAME | TECHNICAL DATA |

| 1 | Forming station | Normally 36stations or more.according to customer drawing to design. |

| 2 | Machine structure | Cast iron arch-type gearbox transmission |

| 3 | Punching | hydraulic punching or merchnical press. |

| 4 | Cutting | Hydraulic post cutting or servo track cutting. |

| 5 | Out table | Manual or automatic. |

| 6 | Computer control system(PLC) | Panasonic or Simens. |

| 7 | Roller material | GCr15,Cr12,SKD11 quenching treatment:HRC58-62(optional) |

| 8 | Driving | Chain drive or gearbox drive. |

| 9 | Forming speed | 0-20m/min. |

| 10 | Raw material request: | Thickness:3.0mm,cold rolled or hot rolled steel,galvanized steel,SS316L/Mild Steel. |

| 11 | Shaft of diameter | Φ100mm quenching treatment (Harbin bearing) |