drywall stud and track roll forming machine

Light steel keel, is a new type of building materials, with the development of China’s modernization, light steel keel is widely used in hotels, terminals, transport stations, stations, amusement parks, shopping malls, factories, office buildings, old buildings, interior decoration Settings, ceilings and other places.light steel keel according to the purpose of the ceiling keel and cut off keel, according to the form of section U, V, C, T, L,unshaped type keel.

Our company’s professional manufacture high-quality Light gauge steel roll forming machine, angle roll forming machine,C/Z/U/W purlin, scaffold Plank , roof panel , cable tray ,highway guardrail and other steel roll forming machine Ect ,No matter what kind of products you need to produce, our equipment can produce perfect products with high precision for you.

We have experience of exporting our wall stud and track roll forming machine to 40 countries all over the world like Argentina, Russia, Australia ,Saudi Arabia ,India,Philippines,Colombia,USA,Canada,UK…. ect .and we won good reputation with good quality.we make different technical solutions according to the profile drawing and requirements of customers,Welcome abroad customer to visit Bigpower Industry.We will offer our best quality products and service for you.

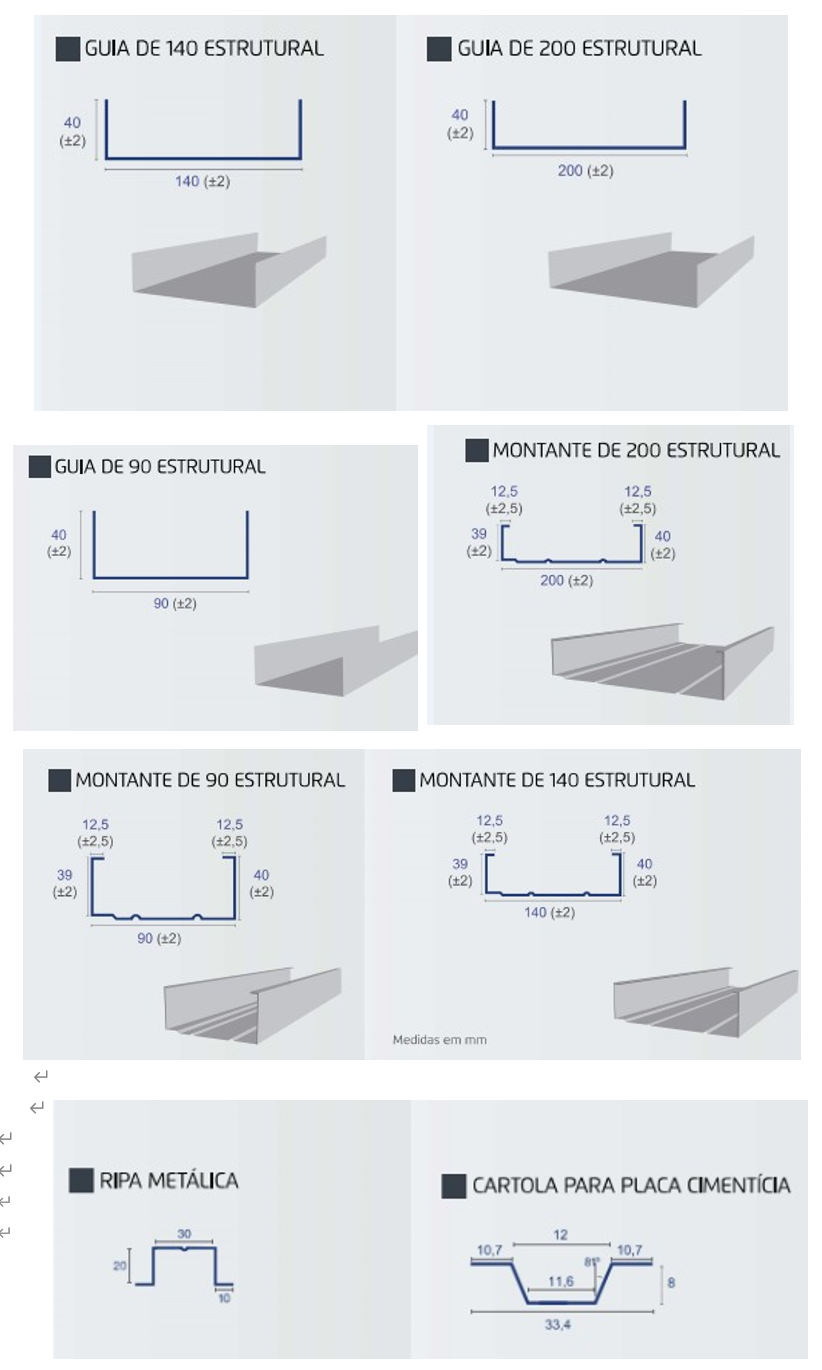

steel framing roll forming machine Drawing:(we can special design as customer request).

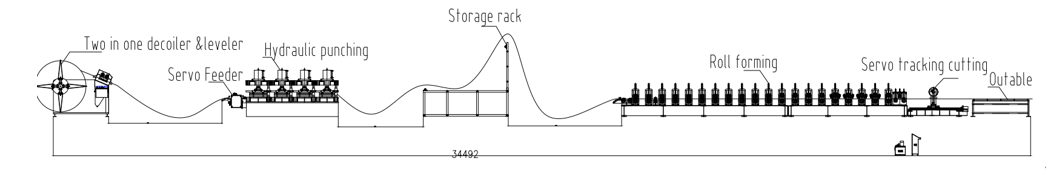

Flowchat:

Specification:

| NO | NAME | TECHNICAL DATA |

| 1 | Uncoiler | Two in one uncoiler&leveller. |

| 2 | Drive | Chain drive or gearbox drive. |

| 1 | Forming station | 12-16stations.according to customer drawing to design. |

| 2 | Machine structure | wall panel style or cast iron rack system |

| 3 | Punching | Hydraulic punching or merchnical press. |

| 4 | Cutting | Hydraulic post cutting or fly saw cutting. |

| 5 | Out table | Manual or auto stacker. |

| 6 | Computer control system(PLC) | Panasonic or Simens. |

| 7 | Roller material | GCr15,Cr12,SKD11 quenching treatment:HRC58-62(optional) |

| 8 | Driving | Chain drive or gearbox drive. |

| 9 | Forming speed | 0-60m/min |

| 10 | Raw material request: | thickness 0.3-0.8mm,0.8-1.5mm Q235,Q345 galvanized steel and hot rolled steel,stainless steel. |

| 11 | Main shaft diameter | Φ65mm. |

| 12 | Cutting method. | AC servo control, ball screw, linear track, servo motor power :3kw |

Customer case:

Drywall roll forming machine sold to Ecuador.

metal stud and trak roll former sold to Argentina.

Four rows drywall roll forming machine sold to Colombia.

Furred ceiling roll forming machine sold to Chile.