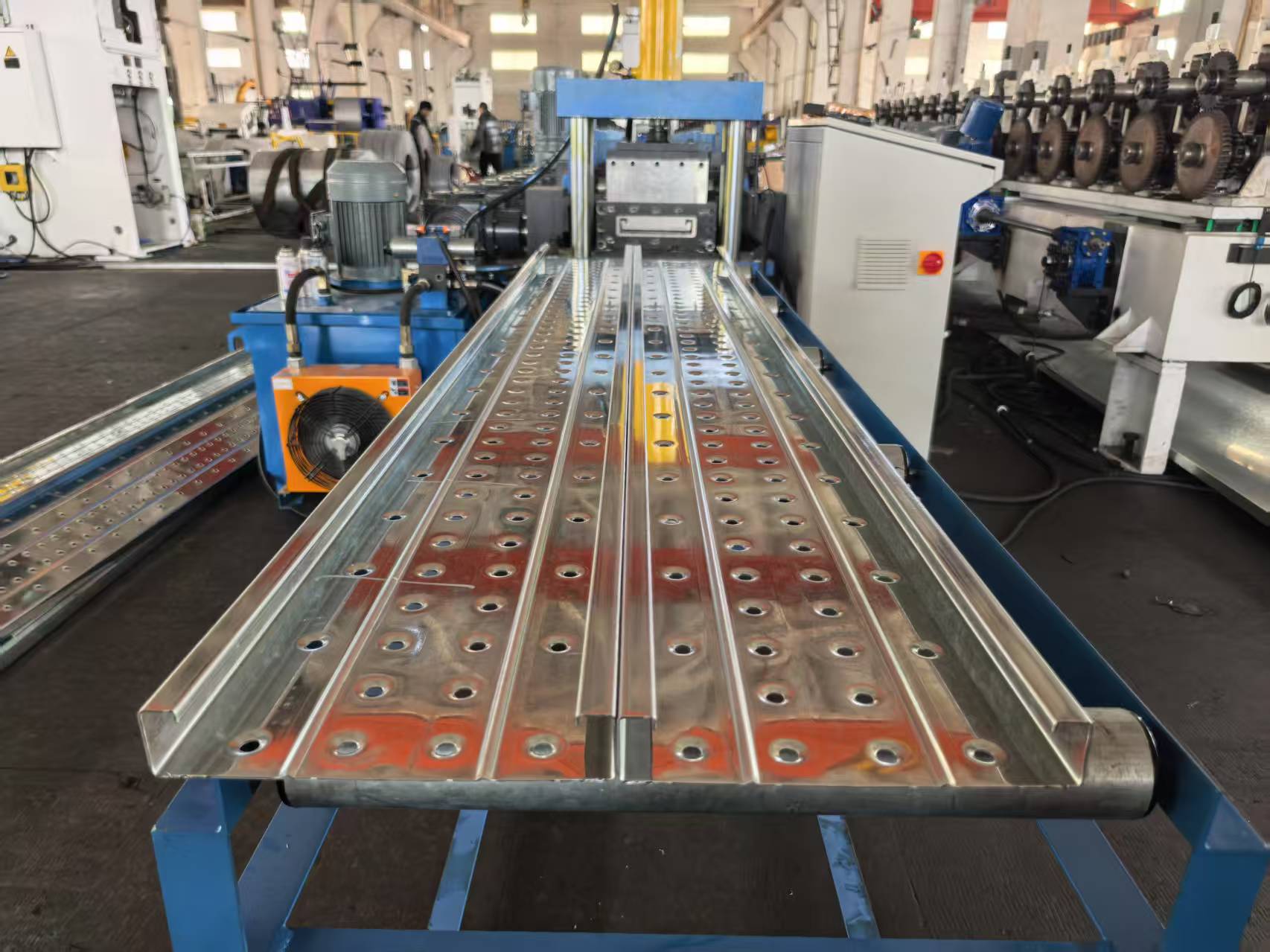

Scaffold walk board roll forming machine

Scaffold plank is very popular in the shipbuilding industry, oil platform, electric power and construction industry and has been widely used.The steel scaffold plank has the characteristics of fire prevention, sand prevention, light weight, corrosion resistance,alkali resistance and high compressive strength.

The steel springboard is a tool to ensure the safety of workers, and it is a commonly used tool in China. There are many materials for scaffolding boards, but steel scaffolding boards are widely used, market-approved,and safe equipment, which can help migrant workers work, improve work efficiency, and reduce safety accidents at work.

We have much experienced in producing the scaffold plank roll forming machine,cable tray roll forming machine,Electrical box panel roll forming machine etc.We can customize the machine according to the customer’s different drawings.We not only sell this machine to well-known domestic brand manufacturers in China, but also export it to South Korea and are well recognized by customers.

Scaffolding Plank Roll Forming Machine Technology Process:

walk panel board roll forming machine specification:

| NO | NAME | TECHNICAL DATA |

| 1 | Forming station | Normally 18stations or more.accroding to customer drawing to design. |

| 2 | Machine structure | wall panel style or Guide pillar archway structure |

| 3 | Embossing machine | Embossing shape according to customer drawing |

| 2 | Punching | You can without punching,or hydraulic punching or merchnical press. |

| 4 | Cutting | Hydraulic post cutting or fly shear. |

| 5 | Out table | Manual or automatic. |

| 6 | Computer control system(PLC) | Panasonic or Simens. |

| 7 | Roller material | GCr15,Cr12,SKD11 quenching treatment:HRC58-62(optional) |

| 8 | Driving | Chain drive or gearbox drive |

| 9 | Forming speed | 0-25m/min |

| 10 | Raw material request: | cold rolled or hot rolled steel,galvanized steel,SS316L/Mild Steel |

Scaffold planks roll forming machine application and advantages:

Traditional bamboo and wood scaffolding is easy to corrode, easy to burn, and easy to cause safety accidents, while angle steel springboards and angle steel mesh panels are also relatively easy to rust. Etc.For the same standard scaffolding board, the weight of the wooden springboard is 1.5-2 times that of the steel scaffolding board, and the wooden scaffolding board is heavier after absorbing water in rainy days, and it is extremely non-slip, and it is easy to cause a safety accident. Steel springboards are relatively light and easy to install.When workers build scaffolding boards, two people are required to lift and transport the wooden springboards, while one person can take 2-4 pieces of galvanized steel springboards, which greatly improves the construction efficiency, and the high strength also reduces the number of scaffolding pipes.

Due to the characteristics of thermal expansion and cold contraction, the wooden springboard cannot be used for a long time after 3-5 turnovers,while the hot-dip galvanized steel springboard has a good anti-rust effect. Treatment gives it a longer lifespan and more turnover.

Customer case:

Scaffold plank roll forming machine sold to Korea.

Foot plate roll forming machine sold to Domestic market.