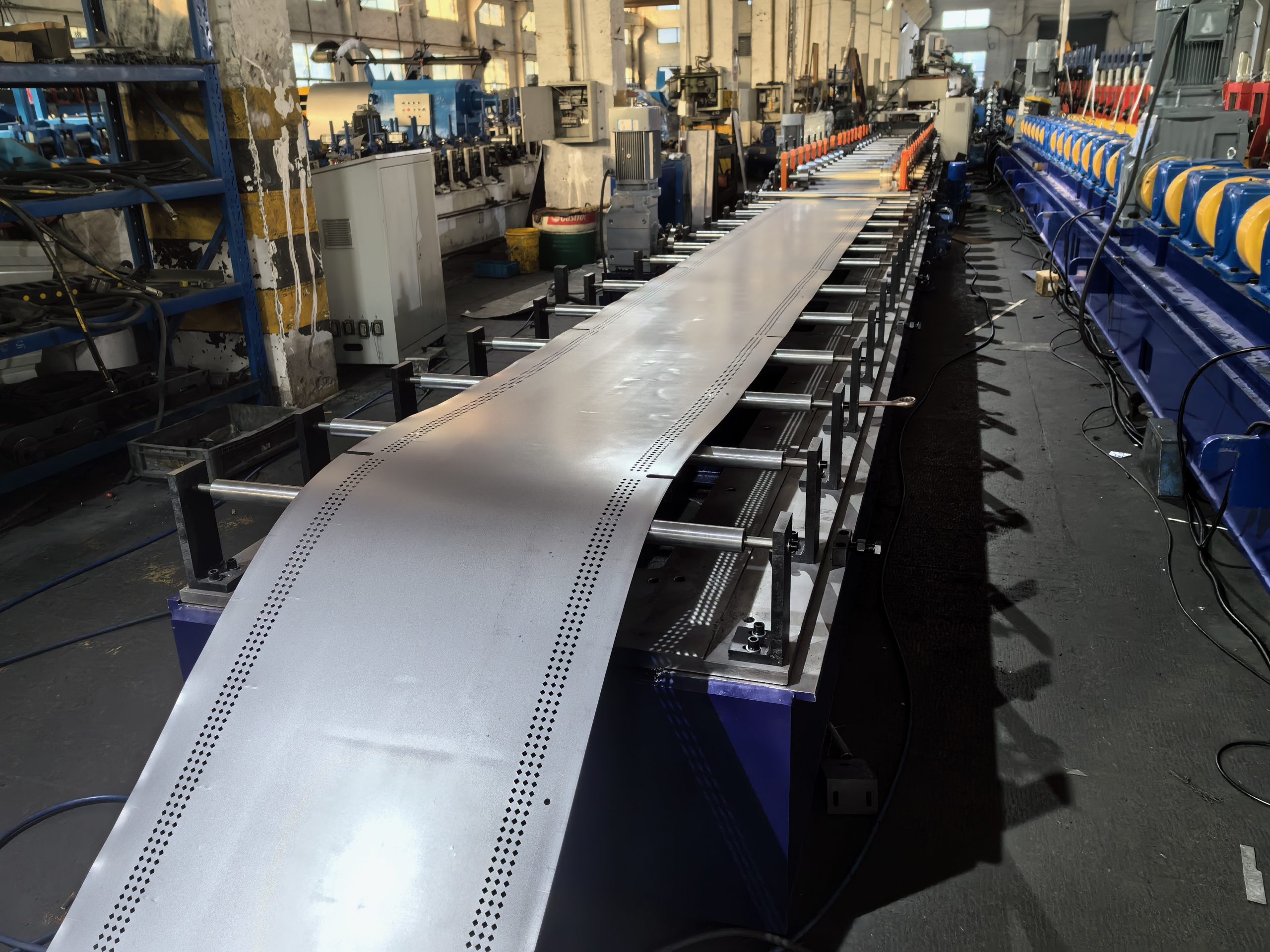

Storage rack shelf roll forming machine

Shelf rack plate roll forming machine is mainly used to produce the shelf rack panel components.This mainly used in warehouses, supermarkets,shopping malls,display, display goods, such as one of the light shelf components.This shelf rack panel is flexible and convenient,simple and economical costs,it can be installed and disassembled quickly.

This shelf panel roll forming machine can produce with different raw materials like:hot-dip galvanized steel,pre-galvanized steel,hot-rolled and cold-rolled steel,stainless steel and aluminum.Thickness range of material is 0.7mm-1.2mm.You could set up many different width for shelf rack panels.

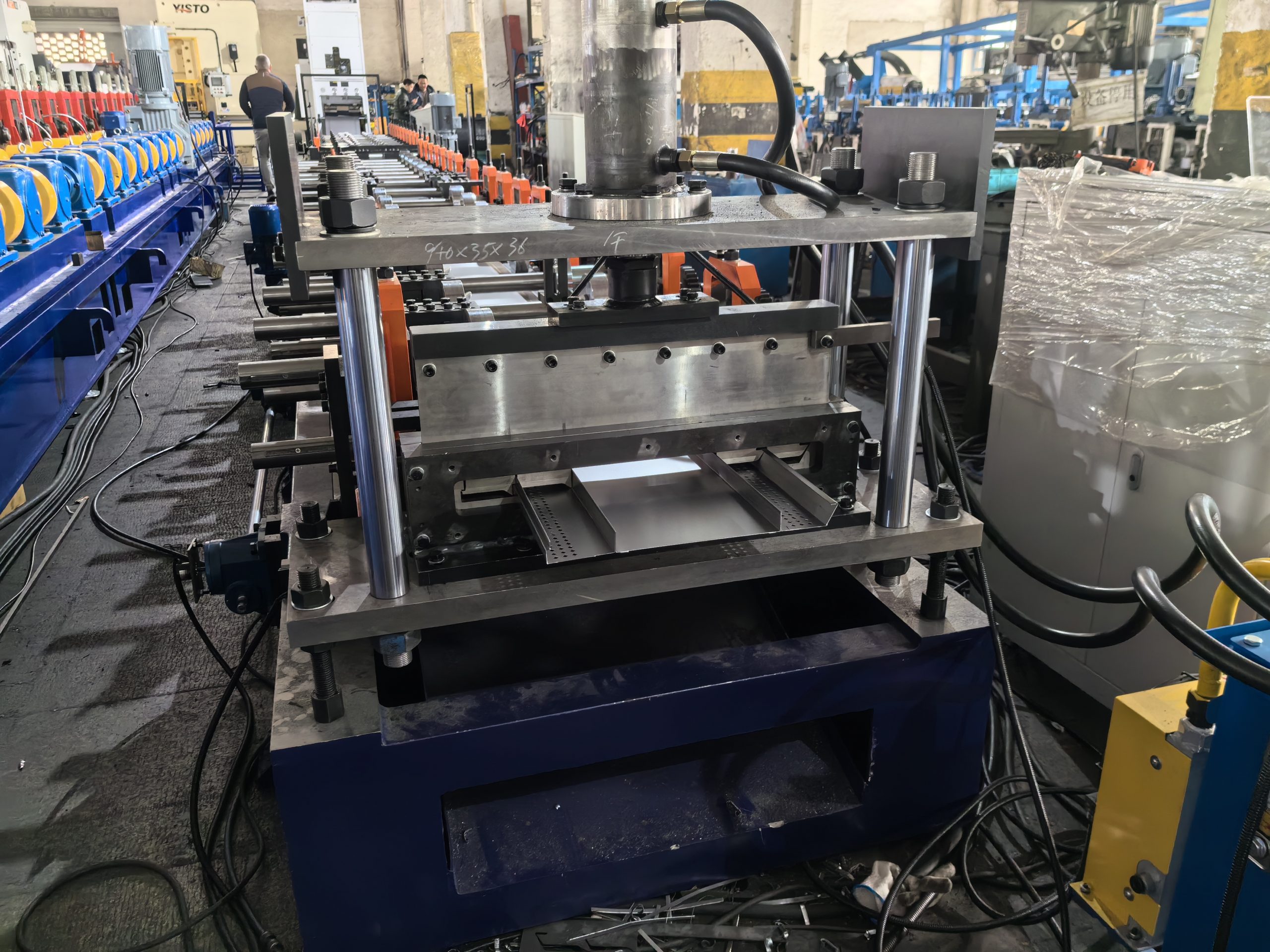

This rack shelf roll forming machine consists of 5T Hydraulic decoiler– adjustable ribs pressing –-lateral holes punching –corner cut— logo stamping ——Roll Forming—hydraulic cutting&folding —Output tables.

Technological process:

Drawing:(Bottom width:200mm-700mm adjustable).

Specification:

| Shelf rack plate roll forming machine | ||

| NO. | Name | Specification |

| 1 | Suitable material | Galvanized Coil,PPGI,Carbon steel Coil. |

| 2 | Uncoiler&leveling combine into one. | 1;Motor:4kw

2.Up3 and down 4 rollers. 3.Expanding diameter:ø450mm- ø530mm |

| 3 | Servo feeding&hydraulic punching system. | Servo motor:3Kw.

Punching mould:1set. Hydraulic power:11Kw. |

| 4 | Holes punching & corner cut | We use hydraulic punching machine

Corner cut mould:1set. |

| 5 | Roll forming Machine | 1)wall panel structure

2) Forming station:22 or 24steps. 3)15KW motor. 4) Machine frame structure:canti-leveler. 5) Structure and the width can be adjustable automatically.(shelf width:200-700mm) 5)Thickness:0.4–1.2mm |

| 6 | Hydraulic Cutting&bending mould combination. | Cutting power:11kw.

Mould material:Cr12.HRC58-62 |

| 7 | Run-out table | Steel frame with Rollers or auto stacker. |

| 8 | Electric control panel | PLC control system,Siemens

Yaskawa inverter from Japan |

| 9 | Hydraulic system | Solenoid is made in China |

Customer case:

Shelf rack panel roll forming machine sold to USA

Shelf rack panel roll forming machine sold to Vietnam.

Shelf rack panel roll forming machine sold to Pakistan.

Shelf rack panel roll forming machine components: