Square pipe roll forming machine

Square pipe roll forming machine consists of:Decoiler — feeding&guide– Leveling — Roll forming machine–Laser welding– rectify–Hydraulic cutting– runout table.

Square pipe roll forming machine overlap adopted the laser welding or use the interlocking the pipe seam.

The square pipes can uses include construction,machinery manufacturing,steel construction,shipbuilding,solar power generation supports,steel structural engineering,power engineering, power plants, agricultural and chemical machinery,glass curtain walls, car chassis, airports, boiler construction, highway railings, building construction, pressure vessels, oil storage tanks, bridges, power plant equipment, lifting and transportation machinery and other high-load welding structural components.Good mechanical properties,weldability,cold,hot working and corrosion resistance, good low temperature toughness.

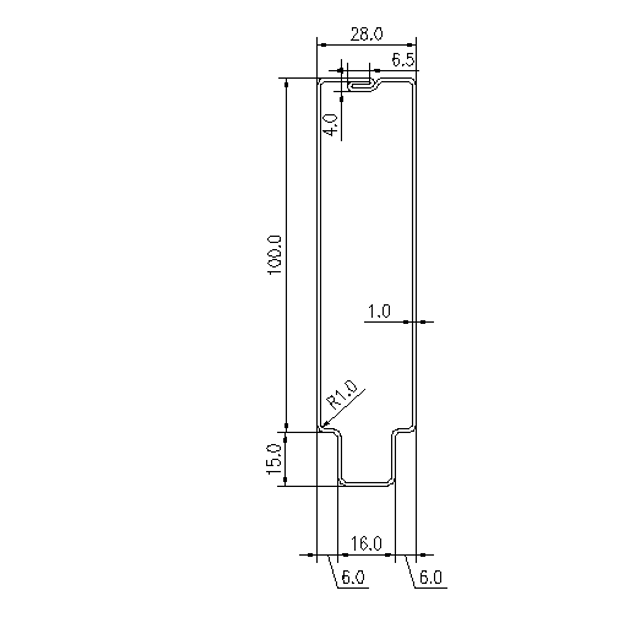

Drawings:

Technological process:

Specification:

| Square pipe roll forming machine | ||

| NO | NAME | TECHNICAL DATA |

| 1 | Forming station | Normally 20stations or more auxilary rollers. |

| 2 | Machine structure | Wall panel style or cast iron rack system. |

| 3 | Punching | Hydraulic punching or merchnical press. |

| 4 | Cutting | Servo track fly saw cutting. |

| 5 | Out table | Manual or automatic. |

| 6 | Computer control system(PLC) | Panasonic or Simens. |

| 7 | Roller material | GCr15,Cr12,SKD11 quenching treatment:HRC58-62. |

| 8 | Driving | Chain drive or gearbox drive. |

| 9 | Forming speed | 0-15m/min |

| 10 | Raw material request: | Thickness 1.5-3.0mm,Q235,Q345 galvanized steel and hot rolled steel. |

| 11 | Main shaft diameter | Φ70mm. |

| 12 | Main motor | 18.5Kw,movable motor:2×0.75kw. |

| 13 | Welding type | Welding power:3Kw |

| 14 | Welding speed | 0-10m/min,continous cooling. Industrial computer mode. |

Customer case:

máquina perfiladora de tubos vendida a España.

Square pipe roll forming machine sold to Brazil.

Square pipe roll forming machine components: