Stainless steel welding pipe machine

Shanghai Bigpower mainly manufacturing decorative& industrial steel tube welding machine with argon gas welding machine and laser welding machine.

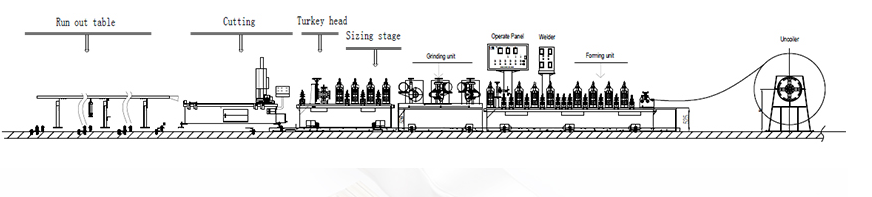

Stainless Steel Welding Pipe Machine with laser welding machine production process:

Single or double side uncoiler-leveling section-forming section-welding stage-online inside weld bead remove section-outside welding bead grind section-first sizing section-in line annealing section-final sizing section and straightening section-nondestructive testing-making strage-fixed length-cut off-end–product upload stage.

Production capacity:0-20 m/min

Welder type: Ultrasonic Welding machine/Laser welding machine

Cutting stage: Metal saw cutting stage/abrasive saw cutting

Material:Our pip making machine can make Stainless steel,Carbon steel,Copper,Iron,MS, GI,Aluminium etc.

Application: Mainly used for decoration, products, appliances stainless steel pipe and carbon steel (round tube, square tube, shaped tube) production. This Steel Pipe making machine with high accuracy, stable performance,High yield,fully automated, simple operation,Continuous production, high efficiency,Less material waste, low production costs,More than 10 years’ lifespan, durable machine.All mechanical parts are processed by high precise CNC center, in order to make all spare parts standardization and uniform

Mainly used for production,industrial products,appliances stainless steel and carbon steel tube,Erw pipes,Titanium pipes(round tube,square tube,special tube).

China pipe welding machine manufacturer Product advantages:

Professional material:its appearance is made up of superior stainless steel engineering material,having the advantage of durability.Precise structure:it uses high-tech the design of elaborate motor structure,having the advantage of stable performance,energy conservation and environment protection.Easy operation:its humanization design of operating system makes

it have the advantage of learn ability and easy operation.

Quality assurance:the products have passed the ISO9001 international quality management system certification,having the advantage of high quality and prestige.

Flowchat:

Stainless steel pipe making machine Technical data form:

The Diameter Of The Tube Ranges From 6mm To 325mm And Thickness Is 0.2mm To 12mm.round pipe, square pipe, rectangle pipe, oval pipe and other irregular pipe as well.

| Model | Horizontal shaft size | Vertical shaft size | Outer diameter range | Thickness | Drive motor | Dimension |

| BP-25 | 30 | 20 | Φ5-Φ25 | 0.25-1mm | 5.5kw | 19.5mx1m |

| BP-40 | 40 | 25 | Φ9.5-Φ50.8 | 0.25-2.0mm | 7.5kw | 21mx1.3m |

| BP-40L | 40 | 25 | Φ12.7-Φ63.5 | 0.25-2.0mm | 11kw | 22.5mx1.1m |

| BP-50 | 50 | 30 | Φ25.4-Φ76.2 | 0.4-2.5mm | 15kw | 24mx1.2m |

| BP-60 | 60 | 40 | Φ50.8-Φ114 | 0.7-3.0mm | 18.5kw | 26mx1.4m |

| BP-70 | 80 | 50 | Φ76-Φ168 | 1.0-4.0mm | 36.5kw | 32mx2.3m |

| BP-100 | 100 | 70 | Φ114-Φ219 | 1.5-4.5mm | 45kw | 43mx3m |

carbon steel pipe welding machines specification:

| NO | NAME | TECHNICAL DATA |

| 1 | Pipe range (mm) | Φ5-Φ219 |

| 2 | Thickness(mm) | 0.5-2.0mm,1.0-5.0mm |

| 3 | Welding speed M/min | 0-20m/min |

| 4 | Speed adjust

|

Frequency conversion stepless speed regulation |

| 5 | Voltage | 220V/380V/440V,60hz,3P |

| 6 | Main motor | 13KW-44KW |

| 7 | Cutting machine

|

Automatic grinding wheel (metal circular saw) cutting machine |

| 8 | Layout

|

P-W-DVHVHVHVVVHVHVHVVH(BX)-V□HVHVHVHV-X-X-V

P : Uncoiler ,W:feeding ,D:zinc removal device , V:vertical,H:Horizontal,BX:zinc spraying, □:grinding, X: turkey head |

| 9 | Reducer

|

Worm gear WPSA80,brand:Famous brand. |

| 10 | Material

|

Galvanized coil,CRC,stainless steel,carbon steel,Alloy metal,Titanium |

| 11 | Pipe length | ≤20M/min |

carbon steel welded pipe making Machine details:

Stainless Steel Welding Pipe Machine delivery photos: