Steel Silo Roll Forming Machine

The steel silo roll forming machine is further divided into welded steel plate silo and fabricated galvanized corrugated plate silo.The fabricated corrugated plate steel silo is formed by rolling and molding various corrugated steel plates and assembled with bolts currently, in the world, fabricated galvanized corrugated steel silos are used for commercial grain storage,ventilation,and drying.The silo walls are manufactured using the roller pressing method.The advantages of the roller pressing method are that the internal stress in the waveform successive molding can be eliminated, the rebound amount is small, and the quality of the produced plate shape is good. Even thicker steel plates can be formed in one step in a pressing plate molding machine, and the rolled plates can be directly processed into corrugated steel products of required specifications.

Grain steel silo machine advantage:

- Light weight and relatively low cost can be matched with conveying equipment with large capacity,Convenient assembly, short construction period, and removable.

- Good air tightness, convenient grain loading and unloading in and out of the warehouse, good water resistance,and suitable for ventilation equipment.

- It can store granular bulk materials such as wheat, barley, sorghum, corn, rice, soybeans, coffee beans, cocoa beans, etc. It can also store powdered materials such as cement, flour, sawdust, starch, minerals, sand,caustic soda,etc.Due to the sealing strip between the bin plate and the bin plate, it can also store water, fuel oil, vegetable oil, etc.

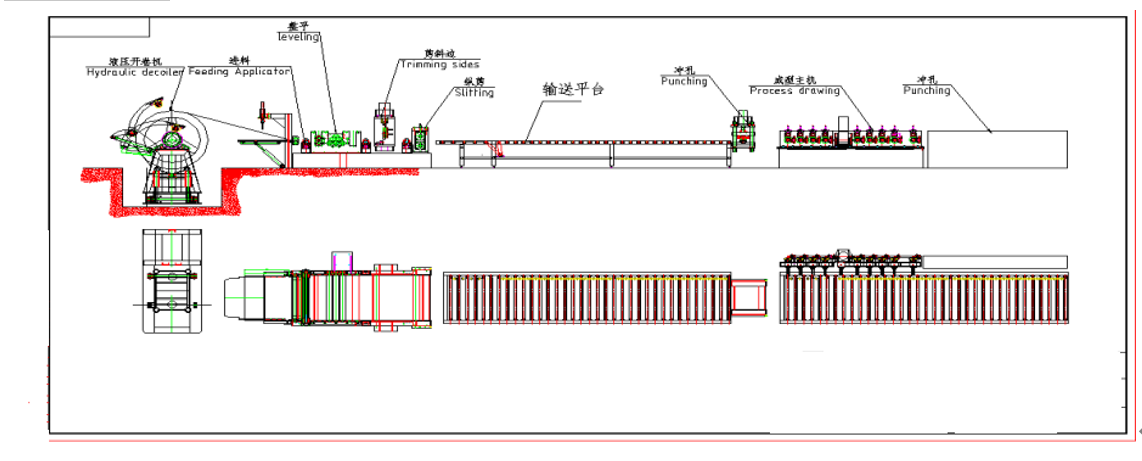

Drawing:(we can special design as customer request):

Grain silo roll forming machine Flowchat:

Steel Silo roll forming machine Specification:

| NO | NAME | TECHNICAL DATA |

| 1 | Uncoiler | Automatic uncoiler or manual uncoiler. |

| 2 | Drive | Chain drive or gearbox drive. |

| 1 | Forming station | 18-20stations.according to customer drawing to design. |

| 2 | Machine structure | wall panel style or cast iron rack system. |

| 3 | Punching | Hydraulic punching or merchnical press. |

| 4 | Cutting | Hydraulic post cutting or follow track cutting. |

| 5 | Out table | Manual or auto stacker. |

| 6 | Computer control system(PLC) | Panasonic or Simens. |

| 7 | Roller material | GCr15,Cr12,SKD11 quenching treatment:HRC58-62(optional) |

| 8 | Driving | Chain drive or gearbox drive. |

| 9 | Forming speed | 2-8m/min. |

| 10 | Raw material request: | Thickness:0.8-3.0mm,1.8-5mm Q235,Q345 galvanized steel and hot rolled steel,stainless steel. |

| 11 | Main shaft diameter | Φ110mm. |

| 12 | Main motor | 110Kw. |

| 13 | Coil width | 1190-1250mm. |

Customer case:

Steel silo roll forming machine sold to Brazil.

Steel silo roll forming machine components: