Track cutting corrugated roof panel roll forming machine

Corrugated roof sheeting roll forming machine has a big range of metal sheet profiles.It includes trapezoidal panel,corrugated panel,roof tile panel,metal deck panel,standing seam panel,wall panel,etc.corrugated metal roofing forming machine products are widely used in roof and wall system in workshop construction and housing construction.The normal machinable thickness range of our roof panel roll forming machine is 0.2mm-0.8mm, the standard or more used in international market is Gauge 26 (0.45-0.5mm), working raw material is Aluminum, PPGI, Galvanized steel, Galvalume steel etc. We confirm machine’s configuration according to your drawing, specially the pitch and height of each wave. The raw material can be PPGI,GI,Stainless steel,Galvalume etc.

We have exported these kinds of roof and wall panel roll forming machine to Argentina,multi holes trapozoidal roof panel forming machine to Russia,we exported many different roof panel machines to South Africa,Colombia,Chile,USA,Mexico,Bolivia, Dubai,Egypt, Brazil,Poland,Ukraine, Kazakhstan, Bangladesh, Bulgaria,Canada, Malaysia,Turkey,Oman,Macedonia,Cyprus,Cameroon, Ghana, Nigeria etc.We make different solutions according to customers’ different drawing,tolerance and budget, offering professional one-to-one service, adaptable for your every need.

In the Construction Industries, we are able to manufacture more machines like hot solar bracket roll forming machine, channel roll forming machine,window&door roll forming machine, furring channel roll forming machine, ceiling T bar roll forming machine, wall angle roll forming machine, purlin roll forming machine, drywall roll forming machine, stud roll forming machine, track roll forming machine, top hat roll forming machine, clip roll forming machine, metal deck(floor deck) roll forming machine, roof/wall panel roll forming machine, roof tile roll forming machine etc.

Technological process:

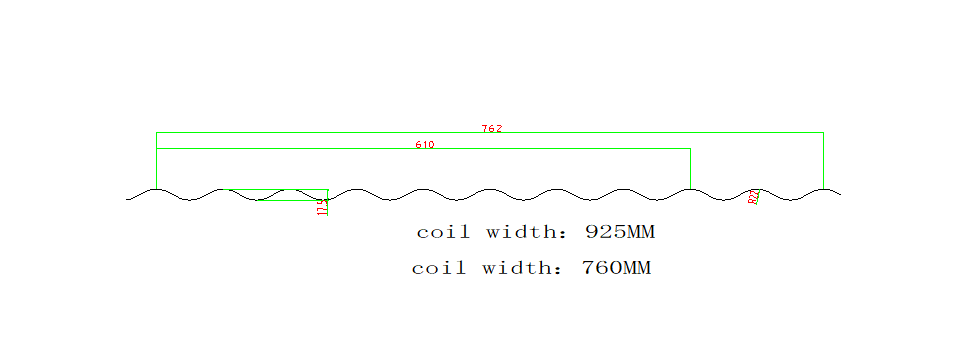

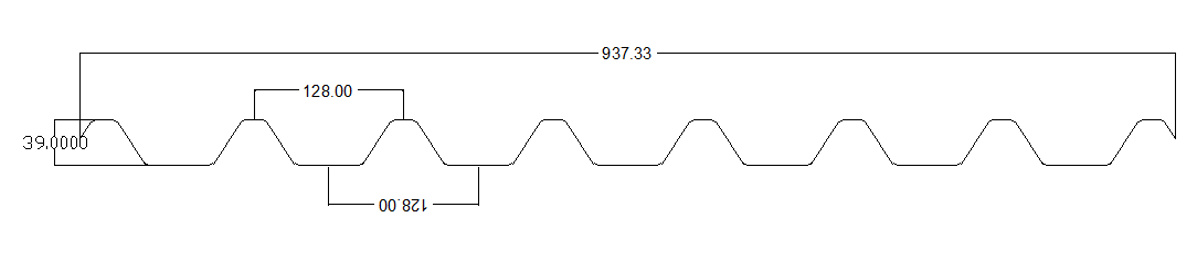

Drawings:

Specification:

| Track cutting corrugated roof panel roll forming machine | ||

| NO | NAME | TECHNICAL DATA |

| 1 | Forming station | Normally 18-28stations or more.accroding to customer drawing to design. |

| 2 | Machine structure | wall panel style or guide pillar style. |

| 3 | Cutting | Hydraulic post cutting or track cutting. |

| 4 | Out table | Manual or automatic. |

| 5 | Computer control system(PLC) | Panasonic or Simens. |

| 6 | Roller material | GCr15,Cr12,SKD11 quenching treatment:HRC58-62(optional). |

| 7 | Driving | Chain drive or gearbox drive. |

| 8 | Forming speed | 0-50m/min |

| 9 | Raw material request: | thickness 0.2-0.8mm,Q235,Q345 galvanized steel and hot rolled steel. |

| 10 | Type | We can make one single layer,double layer,triple layers. |

| 11 | Main motor | 11Kw with accumulator. |

| 12 | Cutting | Servo track cutting. |

Customer case:

Trapozoid roof panel roll forming machine sold to South Africa.

Track cutting corrugated roof panel roll forming machine sold to Argentina.

Corrugated roof panel machine sold to Chile.

Anechoic plate roll forming machine sold to Russia.

Trapozoid roof panel forming machine sold to Mexico.

Trapozoid roof panel roll forming machine sold to USA.

Track cutting corrugated roof panel roll forming machine components: