Warehouse Shelf Rack Roll Forming Machine Wholesale

Warehouse shelf rack roll forming machine uses coiled metal steel strips as raw materials, which are made into specific shapes and specifications after uncoiling, continuous forming and cold bending,and automatic fixed-length cutting.The whole machine adopts PLC control and AC frequency conversion speed regulation technology to realize continuous automatic production. It is an ideal production equipment for warehouse and industry zone.

This shelf upright roll forming machine can produces 3 different sizes in one machine according to automatic traverse of the frame and replace shearing blades when producing different specifications.The machine punching with 110T punching press and with 20stations to forming the shapes.Machinable thickness is from 1.5-3mm with raw material cold-rolled steel,galvanized Coil,PPGI,Carbon steel,Stainless Steel and Aluminum.

Our warehouse pallet rack roll forming machine is applied to warehouse,supermarket,industry,logistics, home,workstation etc.Until now,We already exporting our C shelf rack roll forming machine and shelf panel roll forming machine to Pakistan,Egypt,Vietnam,India,South Africa,Brazil etc.In warehouse pallet racking system, we are able to manufacture more machines like Sigma beam roll forming machine,P beam roll forming machine,Z beam roll forming machine,Box beam roll forming machine,step beam roll forming machine and shelf board roll forming machine etc.If you are interested in this machine,please contact Bigpower. We will offer 24 hours online service a

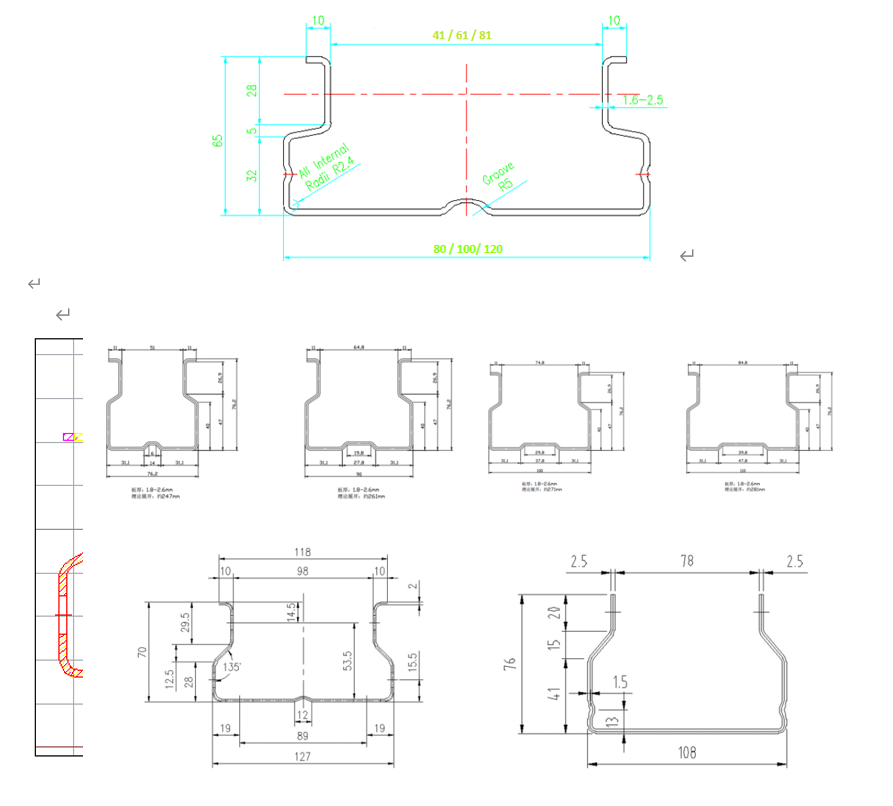

Drawing:

Technological Process:

Specification:

| NO | NAME | TECHNICAL DATA |

| 1 | Forming station | Normally 20stations or more.accroding to customer drawing to design. |

| 2 | Machine structure | Cast iron arch-type gearbox transmission (through-shaft traverse structure) or chain drive |

| 3 | Punching | You can without punching,or hydraulic punching or merchnical press. |

| 4 | Cutting | Hydraulic post cutting or servo track cutting |

| 5 | Out table | Manual or automatic |

| 6 | Computer control system(PLC) | Panasonic or Simens |

| 7 | Roller material | GCr15,Cr12,SKD11 quenching treatment:HRC58-62(optional) |

| 8 | Driving | Chain drive or gearbox drive |

| 9 | Forming speed | 0-25m/min |

| 10 | Raw material request: | thickness 1.5-3.0mm,Q235,Q345 galvanized steel and hot rolled steel.carbon steel,cold steel. |

| 11 | How to adjust sizes? | Roller mold: 1 set (completed by the automatic traverse of the frame when producing different specifications),The shearing blade needs to be replaced when producing different specifications) |

| 12 | Main motor power | 22Kw |

Customer case:

Shelf rack roll forming machine sold to Pakistan.

Shelf rack roll forming machine sold to Vietnam.

Machine components pictures:

Customer inspect products show: